3D Printing Services Business

This is a blog post about my experience with running a 3D printing services business.

I had been thinking about doing something on the side for a year or so. But I didn't know of anything I wanted to do. In the middle of 2022 I was looking for something new to do and so I got into 3D printing. At first it was completely a hobby and then I got into FPV Drone racing/flying late 2022. There I started designing my own 3D prints for certain things in the hobby. I didn't want to keep letting time go by as I was trying to come up with an idea I wanted to do for a business so I just started selling 3D printing services. That way I could start paying my "idiot tax" and learning lessons while I keep thinking of an idea I want to do.

📝 Finding a Name: Hollplex

The name Hollplex and how I got to it isn't any super interesting story. I was trying to think of a name for the greater part of a month and as I mentioned I was tired of waiting and just wanted to act at this point. I tried to pull inspiration from everything, planet names, rivers, animals, other companies, star names, etc. I wanted a business name that wasn't too specific, wasn't overly hard to spell and also that the domain for it was open and cheap. I ended up looking at the names of numbers and the largest named number happen to be a googolplex. So I mended my last name and that into Hollplex and here we are.

🛠️ Starting Out on Treatstock

My first sales were on a manufacturing services platform called Treatstock. Treatstock was a site where you could set up a store page that provides manufacturing services like 3D printing, plastic injection, laser cutting, CNC machining, anything really. Then other people could go on the site and whatever service they needed the site would list all the stores providing that service and you could filter through them by price, rating, number orders etc. So I made a store there and waited for orders to come through. I did some research and had marked my pricing to be right at the lowest than anyone else. I know this isn't the best business strategy to compete on price but remember I wasn't really doing this to make money, I was doing it to pay business "idiot tax" and learn lessons. I started to get a few orders and everything was good. Treatstock rewards fast manufacturing and shipping so once an order came in you needed to work fast. Typically you had 2 maybe 3 days tops to manufacture an order and ship it out. Sometimes I found myself starting a 4-6 hour print that didn't end till 4am so I would set alarms to wake up in the middle of the night, go remove the print and start another so I could not get dinged by Treatstock.

One time I was running low on plastic resin to print with and I started a 8 hour print right before bed, I was worried the resin tank would run dry and I'd lose all that time. I had some resin of a different brand but didn't want to mix it in mid print as that would cause the print to come out weird. So I went to bed and set alarms for every hour, where I'd get up and go check on the print and if it was dangerously low, I'd make the decision to mix in the other brand of resin I had. After several alarms and me going and checking on it, it wasn't till about the 4th or 5th hour that when I got back in bed after checking on the print, that I never woke up for the remaining alarms, I was so tired and beat from constantly waking up, going to the printer, checking on it and then going back to bed that my body just said enough and slept through the remaining alarms. The print however did finish okay and the resin tank just barely didn't run dry.

😓 Treatstock Pains

I didn't like the platform Treatstock and ended up getting burned by them actually. There were alot of bugs and issues with the site and when I would reach out for help I never got a response. They took a lot of the revenue from orders as well, it was something like a few dollars flat fee and then a percentage as well of the order. Then when you went to transfer your balance to your bank account, they took another percentage, saying I didn't fill out certain tax forms that I had actually filled out. So I ended up paying taxes twice or the U.S. tax and then Treatstocks own tax on top of the cut they took. Of course I reached out about this and still no response from them. I checked on their social media accounts and all of them stopped posting at the same time a year ago. So I believe the website just runs a ghost crew, no one actually works for Treatstock, maybe just one guy that keeps the site up as long as it's taking in money.

💰 The Challenges of Quoting and Pricing

The other problem, and this is kind of an overall 3D printing services problem, is quoting. Treatstock would give customer's instant quotes, so I had to set my pricing. They let you set your pricing by type of resin like tough, flexible, etc. then by the weight of the print. So when someone went to the site, they would upload their 3D print STL file and the site would calculate how much weight that would be and give them a quote for you instantly. The problem with that is there are other variables that can affect my cost to manufacture this quoting model doesn't account for. For example, someone's object they want 3D printed, depending on how complex the item is, dictates orientation and support structure of the item. The item could be very detailed, small and delicate. So although the item does not weigh much, I needed to spend hours setting up a good support structure to print the item in and then spend time carefully removing each support so as to not break the item. To compensate for this quoting issue you had to hike your pricing, but then if someone wants something really small and simple, like some little square dice perhaps, they would never buy from me since the pricing they would get would be really high and not make any sense.

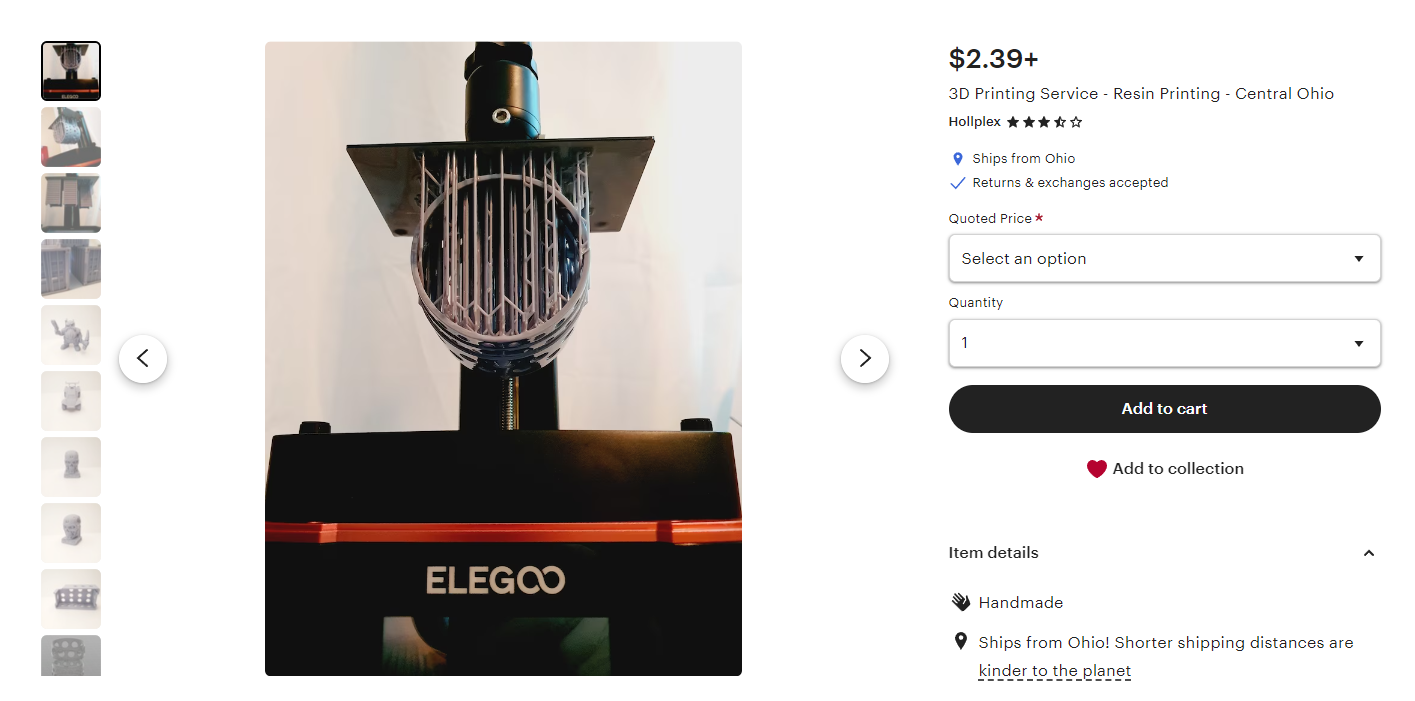

🔄 Transitioning to Etsy and Direct Sales

I eventually left Treatstock and set up an Etsy store page. There I made a generic listing for a 3D printing service and also listed my designs I made myself on the Etsy store. But while I was on treatstock, I had someone find my website through my Treatstock store page and reach out directly to me. They became my main customer, sending me orders often for various things they needed printed and I used Etsy as some kind of payment processor through that generic printing service listing. This person wanted prints mostly in flexible resin, which is some of the most expensive resin and also the hardest to print. They most likely found me sense I offered flexible resin printing and sense I was competing on price, had the lowest price by far. Kind of like in War Dogs, where they were just some little guys that quoted so far under anyone else. What I saw others pricing flexible prints for, I was quoting so well under that, that it was hard to say no. But I learned why flexible prints cost the most. You have to spend a lot of time carefully slicing the model with supports and go through several failures. I went to war printing some 3D models and reprinted items 5-6 times in some cases. I got pretty good at resin 3D printing because of this. I was constantly printing, running my printer 24/7. Most prints took around 6 hours, so first thing in the morning I would remove a print and start another, then do the same after my day job, and then again right before bed.

🎓 Lessons Learned

Some of the business lessons I learned along the way would be to understand customer expectations. Everyone is different and some people just have a different vision for what they are buying and it's a good idea to get ahead and understand that first, that way you can make sure to meet their expectations. I would have some customers love the prints I made and others hold them to a high level of scrutiny. I also learned what I think of as the Burger King vs Canes Chicken model. Burger King has a menu with different items on it and will make it your way, you can customize anything. Where on the other hand, Canes has effectively one menu item and your customizability is just in quantity, how much you want. I think both models have their purpose but I see a lot more success coming from Canes model. I always see a line wrapped around Canes but not so much Burger King you know. I learned this when I started offering coloring to my prints. I gave a customer a list of all my types and brands of resin. Then gave them a list of all the colors I could add to the resins and said I could make anything they wanted. Not to this customer's fault, but I got orders for prints that contained 2-3 different types of resin and 1-2 different types of coloring. For example 75% Flexible, 25% tough with blue and orange ink 50:50. This caused me to have to make these mixtures, printing one item or so, and then either toss the excess resin or buy containers to store this one off mixture in (see image below). It was fun and I learned alot about 3D printing with mixes and inks but for a one man operation you need to stay lean and mean. Offer one thing and stick to it until that fountain is dry.

🎁 Wrapping Up

After about a year of doing this 3D printing service I had gotten out of it what I wanted and was ready to do other things. I tried to keep up with it but it just took too much time. I'm really glad I did it though, I learned alot about 3D printing and also about business. I learned about customer service, quoting, pricing, and also about the 3D printing industry. I'm sure I'll have what I am working on now posted somewhere on this blog so if you're interested, join the newsletter or reach out. Thanks!